As the world intensifies its efforts to combat climate change, innovative technologies are emerging to effectively reduce carbon emissions, particularly in the automotive industry. Among these, Metal-Organic Frameworks (MOFs) and Temperature Swing Adsorption (TSA) technology stand out as promising solutions. At Autoxona, we’re excited to explore how these advanced technologies work, their potential to revolutionize carbon capture and storage, and how they can be integrated into vehicles to pave the way towards a cleaner, greener future.

Understanding MOFs

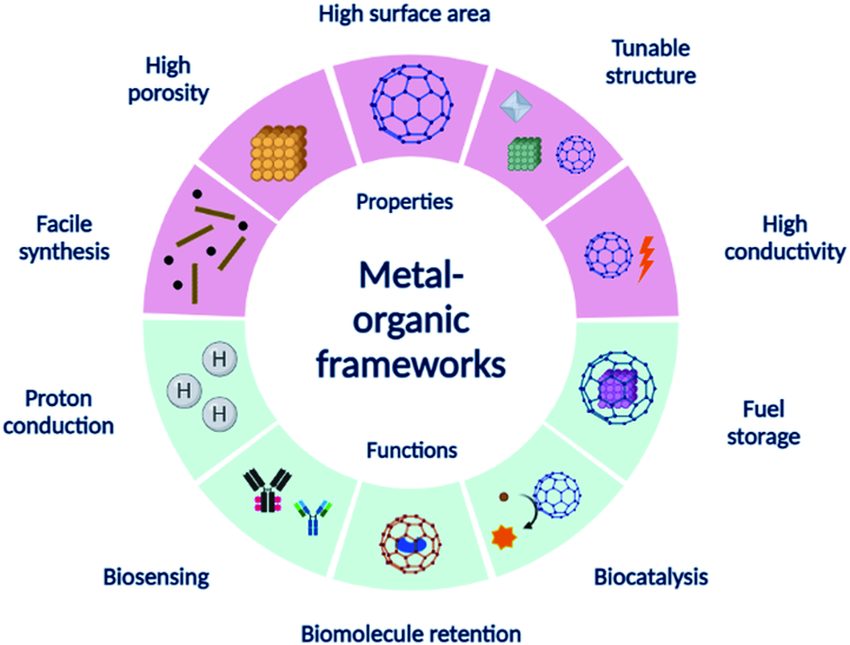

Metal-Organic Frameworks (MOFs) are a class of crystalline materials composed of metal ions connected by organic linkers. These structures create highly porous networks capable of trapping gases, including carbon dioxide (CO2). MOFs are renowned for their exceptionally high surface areas and customizable properties, making them ideal candidates for gas adsorption applications.

Key Features of MOFs

- High Surface Area: MOFs have an exceptionally high surface area, with just one gram of MOF having a surface area equivalent to a football field. This allows for the adsorption of a significant amount of CO2.

- Tunable Pore Sizes: The pore sizes of MOFs can be adjusted to selectively capture specific gases. This tunability ensures that MOFs can be optimized for maximum CO2 capture.

- Chemical Versatility: The chemical properties of MOFs can be modified to enhance their affinity for CO2, making them highly efficient at capturing carbon emissions.

How Do MOFs Work?

The structure of MOFs allows them to capture CO2 through physical adsorption. The large surface area and adjustable pore sizes enable MOFs to selectively adsorb CO2 from gas mixtures. This process involves:

- Physical Adsorption: CO2 molecules are trapped within the pores of the MOF material.

- Selective Binding: MOFs can be engineered to preferentially bind CO2 over other gases, enhancing their efficiency in capturing carbon emissions.

Temperature Swing Adsorption (TSA)

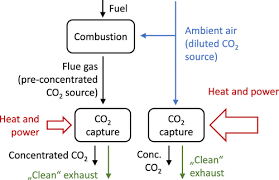

Temperature Swing Adsorption (TSA) is a process used to regenerate adsorbents, such as MOFs, after they have captured CO2. In TSA, the adsorbent is exposed to varying temperatures to release the captured CO2, allowing the adsorbent to be reused.

How Does TSA Work?

- Adsorption Phase: At a lower temperature, the MOF adsorbent captures and stores CO2 from a gas stream.

- Desorption Phase: The temperature is increased, causing the MOF to release the captured CO2. The released CO2 can then be collected for storage or utilization.

- Regeneration: The MOF is cooled down and ready to capture CO2 again, completing the cycle.

Benefits of Using MOFs and TSA Technology

- High Efficiency: MOFs have a high capacity for CO2 adsorption due to their large surface areas and tunable pore structures.

- Selective Capture: MOFs can be engineered to selectively capture CO2, making them highly efficient for carbon capture applications.

- Regenerability: TSA technology allows for the continuous use of MOFs by efficiently regenerating them after CO2 capture.

- Scalability: Both MOFs and TSA technology have the potential to be scaled up for industrial applications, making them viable for large-scale carbon capture projects.

Applications of MOFs and TSA in Reducing Carbon Emissions from Vehicles

- On-Board Carbon Capture Systems: MOFs can be integrated into vehicles as part of an on-board carbon capture system. These systems can capture CO2 emissions directly from the vehicle’s exhaust before they are released into the atmosphere. This application is particularly relevant for internal combustion engine vehicles, where capturing and storing CO2 can significantly reduce overall emissions.

- Hybrid Systems: Vehicles equipped with both traditional engines and MOF-based carbon capture systems can operate more cleanly. The captured CO2 can be stored on the vehicle and then offloaded at designated facilities for further processing or utilization.

- Electric Vehicles (EVs) and Renewable Energy Integration: While electric vehicles themselves do not emit CO2 during operation, the production of electricity used to charge them often involves CO2 emissions. MOFs and TSA can be applied at power plants to capture CO2 emissions, ensuring that the electricity used for EVs is greener.

Installing MOF and TSA Systems in Vehicles

To integrate MOF and TSA technology into vehicles, several components and steps are necessary:

- Adsorption Chamber: An adsorption chamber filled with MOF materials is installed in the vehicle’s exhaust system. This chamber captures CO2 from the exhaust gases.

- Temperature Control System: A temperature control system is installed to manage the TSA process. This system adjusts the temperature of the adsorption chamber to release captured CO2 and regenerate the MOF materials.

- CO2 Storage Tank: A storage tank is added to the vehicle to store the captured CO2 until it can be offloaded at a designated facility.

- Control Unit: A control unit is installed to monitor and manage the entire carbon capture system, ensuring optimal performance and efficiency.

Installation Process

- Assessment and Design: Engineers assess the vehicle’s exhaust system and design a custom MOF and TSA system that fits the vehicle’s specifications.

- Component Installation: The adsorption chamber, temperature control system, CO2 storage tank, and control unit are installed in the vehicle. This may involve modifications to the exhaust system to accommodate the new components.

- System Integration: The installed components are integrated into the vehicle’s existing systems, ensuring seamless operation. This includes connecting the control unit to the vehicle’s computer system.

- Testing and Calibration: The carbon capture system is tested and calibrated to ensure it operates correctly and efficiently. This step includes checking for any leaks and verifying the system’s ability to capture and store CO2.

- User Training: Vehicle owners are trained on how to use and maintain the carbon capture system, including how to offload captured CO2 at designated facilities.

The Future of MOFs and TSA Technology in Automotive Applications

The development and deployment of MOFs and TSA technology hold significant promise for reducing carbon emissions from vehicles. Ongoing research aims to improve the efficiency and cost-effectiveness of these technologies, making them more accessible for widespread use. Collaboration between academia, industry, and government is crucial to advancing these technologies and integrating them into existing carbon reduction strategies.

Research and Development

- Enhancing MOF Performance: Scientists are working on developing MOFs with even higher surface areas and better selectivity for CO2. This includes creating new MOF structures and optimizing existing ones specifically for automotive applications.

- Scaling Up Production: Efforts are underway to scale up the production of MOFs to meet the demands of automotive applications. This includes developing cost-effective manufacturing processes and ensuring the quality and consistency of MOF materials.

- Integration with Vehicle Designs: Engineers are exploring ways to seamlessly integrate MOF-based carbon capture systems into vehicle designs without compromising performance or aesthetics.

Autoxona’s Commitment

At Autoxona, we are dedicated to promoting and supporting innovative technologies that contribute to a sustainable future. By providing information and resources on cutting-edge solutions like MOFs and TSA technology, we aim to raise awareness and encourage the adoption of practices that reduce carbon emissions in the automotive industry.

Conclusion

The use of Metal-Organic Frameworks and Temperature Swing Adsorption technology represents a significant advancement in the field of carbon capture and storage, especially for vehicles. These technologies offer efficient, scalable, and sustainable solutions to the pressing issue of carbon emissions. By embracing and investing in these innovations, we can move towards a greener future and mitigate the impacts of climate change.

Stay tuned to Autoxona for more insights and updates on the latest developments in sustainable technology and carbon reduction strategies. Together, we can drive towards a cleaner, healthier planet.

But until breast cancer is eradicated, until a cure is found, and prevention discovered, the only way to combat the horror is through empowerment that deliciously freighted expression that conveys education, resources, support, and, in the case of these women, a whole lot of attitude